Laser Cleaning

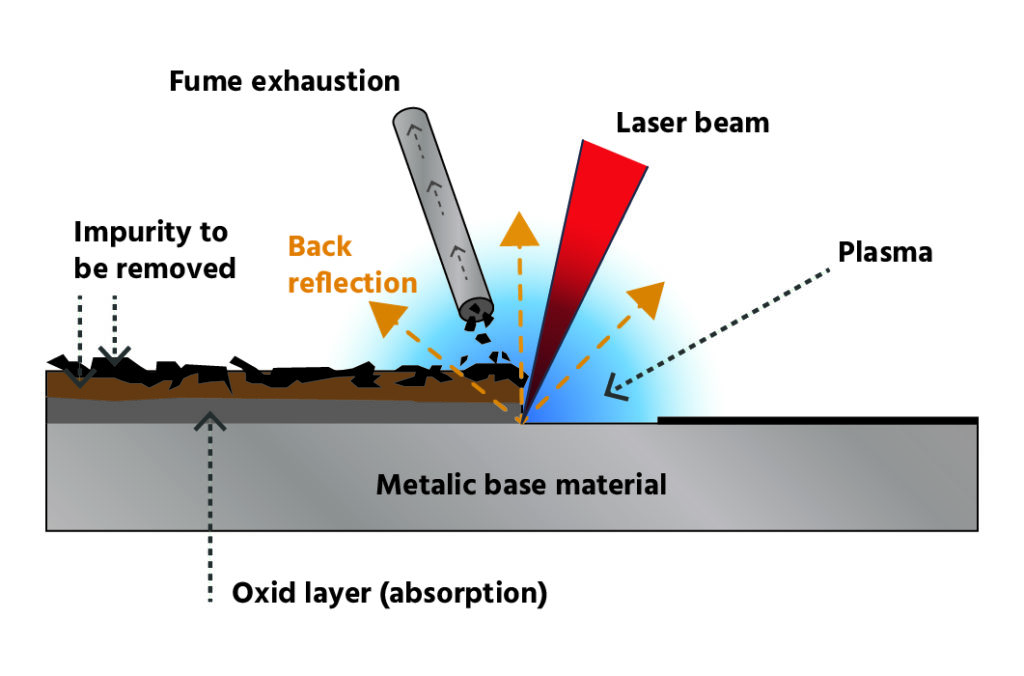

Today, laser cleaning is a general term that includes many other methodologies and technologies. The basic principle of the process is the complete or partial removal of layers from a base surface, material, or substrate, at thicknesses from 1 to 1000 μm, and at a high speeds measured in cm²/s. In defined conditions is possible to remove metal, plastic/polymer, and glass/silicate layers, or even organic materials.

Laser cleaning is always a combination of three basic processes – vaporisation, sublimation, and disruption of adhesion, i.e. the bonds between the removed and base material. The base material is minimally affected thanks to the laser beam’s short and very powerful pulses that contain very little heat input. In certain cases the laser process is inert to the base material, and thus does not cause any changes to its surface or internal structure.

SPYRE Technology

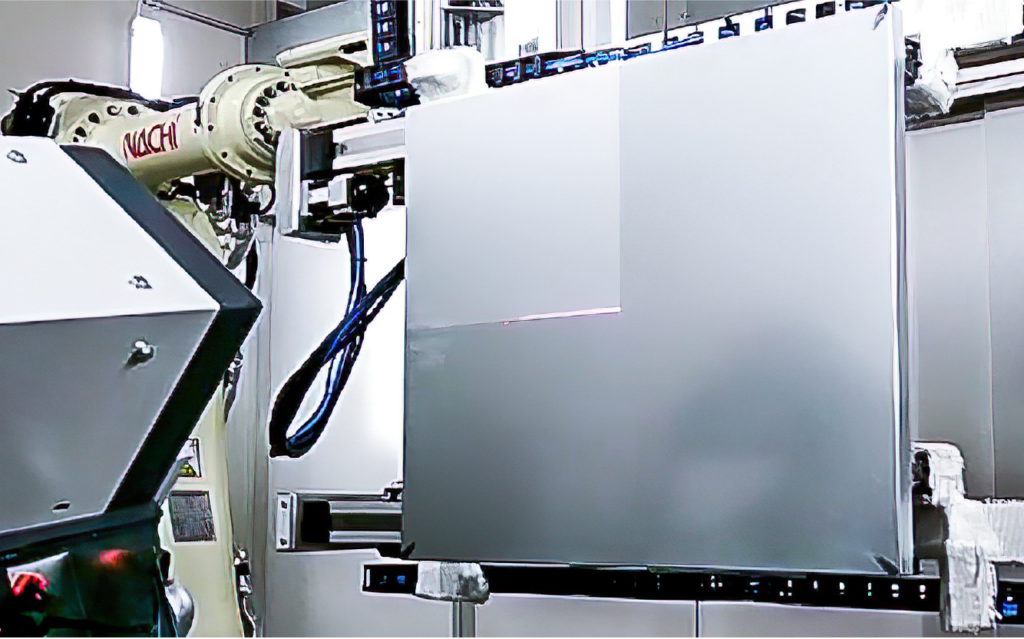

HEAVY-DUTY, BUILT FOR INDUSTRY

Having a robust mechanical construction enables long-term work in more demanding conditions than is standard for other laser cleaning configurations. We adapt the technology to the required application, and we implement the required means for the stability of the serial process.

ACTIVE COOLING AND HEATING OF MAIN COMPONENTS 24/7

To ensure sustainability, we work with components that we can control in various working conditions – actively adjusting the required temperature and flow of the cooling medium. This serves to prevent problems that might otherwise frequently occur due to overheating or low temperatures during the process.

GREEN TECHNOLOGY

SPYRE laser technology is designed so that no future need arises for the disposal of hazardous materials originating from the laser cleaning process, and no additional costs or energy requirements arise during the laser process or waste management.

LASER PROCESS QUALITY

Thanks to the use of high-quality optical components, SPYRE technology allows us to use maximum possible laser power, thereby increasing process efficiency and speed.

LASER SAFETY

We make sure our machines comply with European standards. For each laser cleaning application, we individually analyse safety risks associated with both direct operation and protective cover.

MEDICAL AND FOOD INDUSTRY USAGE

SPYRE laser systems can even be implemented in environments demanding extreme cleanliness and process stability, e.g. processes in the medical and food industries, which demand high quality and surface cleanliness.

Terminology

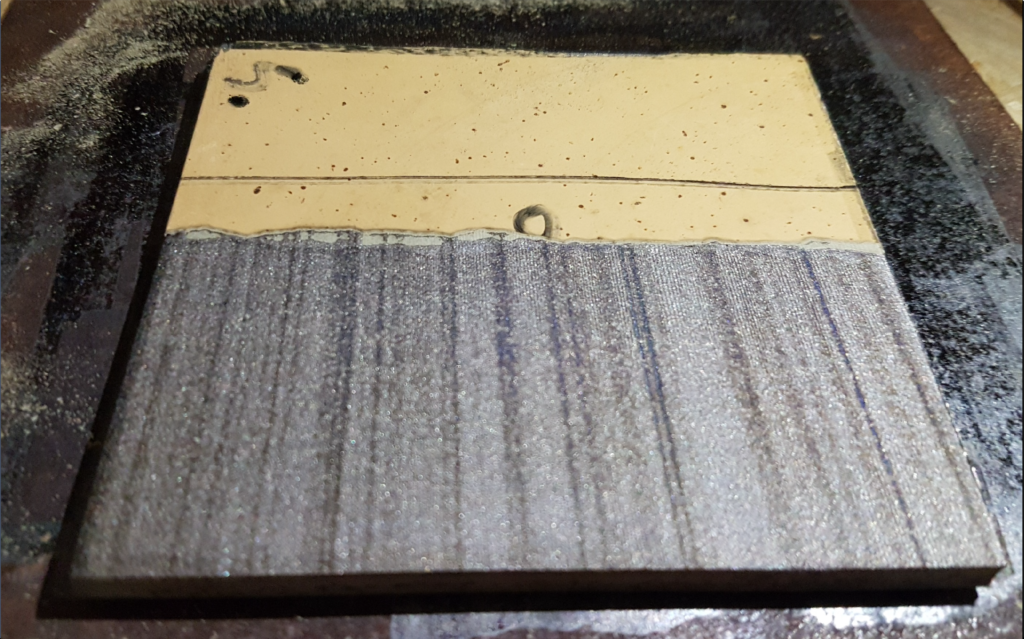

The basic principle of laser decoating is the partial removal of thin vapour-deposited, sputtered, or varnished layers, with thickness measure in units of μm, to preserve the visual and functional properties of the base material. This process does away with masking individual parts and so eliminates maintaining jigs and simple changes to the pattern that is removed from the base material. Because of the frequent use of the process on visible or exposed surfaces, the process must meet high requirements for accuracy and homogeneity of the result.

A commonly used base material is polymer, from which metal layers – such as aluminium, iron, chromium, or other layers with a polymer or metal base – are removed. We use 10–100 W lasers with a very short and powerful pulse that has minimal impact on the base material, which guarantees a wide possibility of layer thicknesses and types of basic materials.

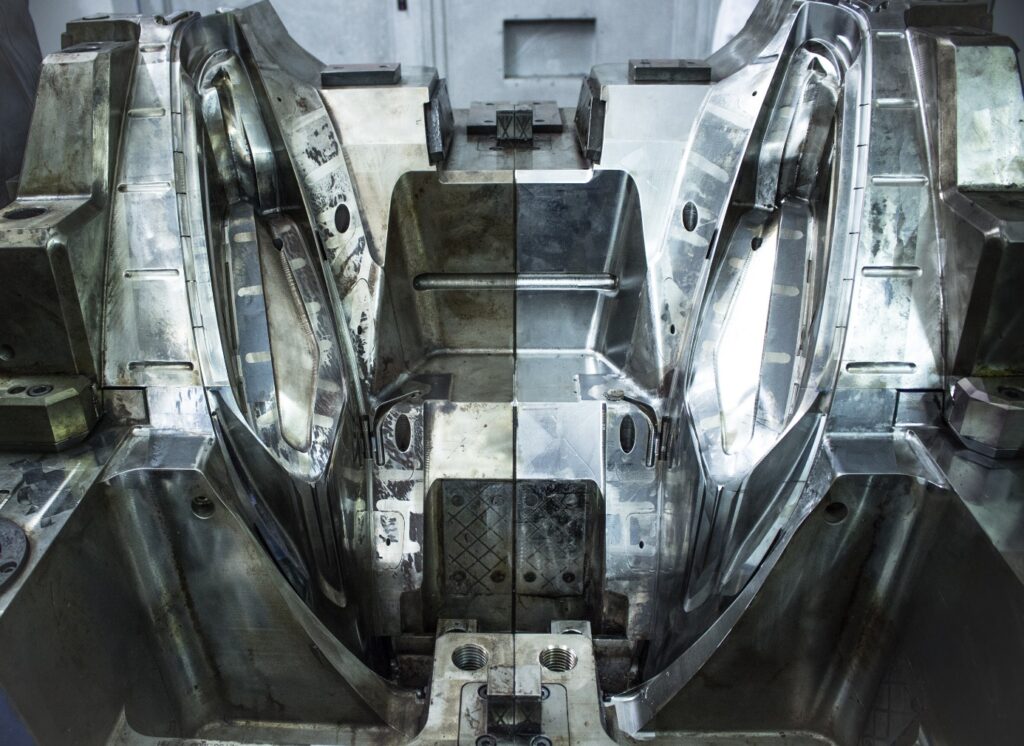

Laser technology is replacing the standard methods of cleaning moulds, such as mechanical and chemical processes. This technology does not generate additional operational costs, or costs for disposing the consumed material.

Using 200–1000 W lasers enables you to remove unequal or inhomogeneous layers, which are created during the everyday use of plastic and rubber moulds. This process combines all the methods mentioned above (sublimation, evaporation, and adhesion) and allows the removal of pressure rust layers (10–50 μm), separator layers, as well as functional contamination (200–600 μm), which contains lubricants mixed with other impurities arising during the process. Under defined conditions, various types of patterns can be cleaned, especially in the rubber industry. Thanks to the minimal influence of the basic material, we do not remove the material from functional surfaces and thus do not disturb the function of the mould.

Surface treatment with laser cleaning is widely used to prepare surfaces before subsequent welding or painting. For preparation before welding, the principle of sublimation is used, and the evaporation of basic operating impurities. At 100–1000 W, preparing surfaces for subsequent processes can be done at high speeds. The main difference compared to mechanical/chemical processes is the minimal disruption of the base material, since the natural passivation layer is not removed. Oxidation layers are completely removed by the laser. This significantly extends the time interval between cleaning and the subsequent welding process.

In the case of preparing weld surfaces for subsequent process (forging, painting), the method we use is to break the bond or adhesion between the removed layer and the base material. The thermal oxidation or silicates formed during the cooling of the weld pool can be removed at the power range of 100–500 W.

The technology used for removing larger paint layers is fundamentally different from the other technologies described. In this case, the gradual removal of the cleaned layer is preferred, making it possible to clean up to 300 μm in one layer without degrading the base material even with repeated exposure.

For the gradual removal of layers at a high power of 500–3000 W with very short pulses, we use sublimation and evaporation in short reaction times. Thanks to this method there is no degradation of the base material. It subsequently retains its original properties, allowing the removal of non-metallic layers from 500 μm up to units of mm, depending on the number of repetitions. It is an efficient method, especially for the removal of lacquer or other layered paints that would otherwise need to be cleaned chemically or pyrolytically, which are economically and logistically demanding.

We perceive the laser removal of metal layers from the metal base material as another technological step following laser decoating. The metal layers are gradually removed in separated layers in the required geometry up to the base metal material, same like in case of LPS method. Each layer is equally removed from the entire surface and similarly to the decoding process. The accuracy is in the tens of μm.

Thanks to the high quality of the beam and laser power (up to 1000 W), we can implement the micromachining process into standard production times. High power also allows the removal of materials with a higher degree of reflectivity of Al, Au, Cu, Pt.