Completely ready-made in-line solution

A fully integrated laser cleaning solution designed for machine builders, system integrators, and production lines. With seamless I/O, RS-232, and TCP/IP communication, it easily integrates into existing manufacturing systems or operates as a stand-alone unit. The system meets European and global standards, with laser safety configured to match specific installation requirements.

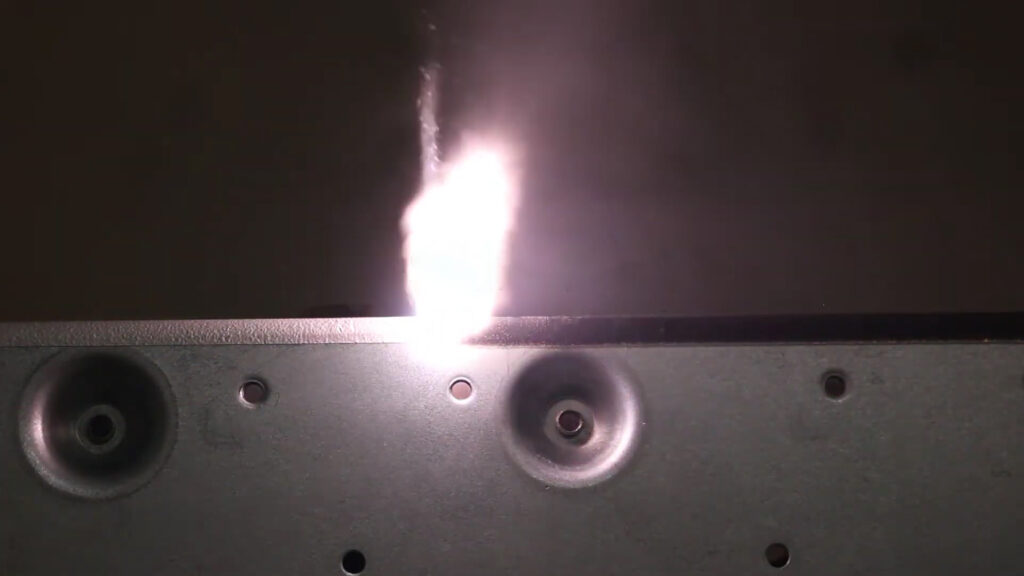

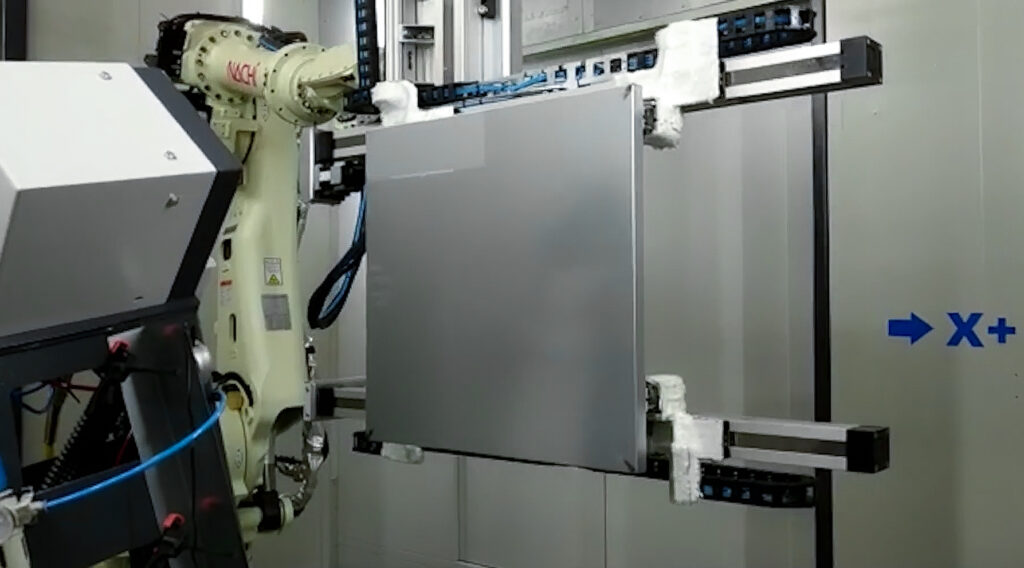

Optimized for robotic applications, our laser cleaning solutions ensure efficient, high-precision cleaning in automated production environments. Robotic arms deliver large-area cleaning while maintaining process stability, effectively removing paint, lacquer, oxides, grease, rust, and dirt from pressing and manufacturing processes. With a broad laser power range from 20 W to 3,000 W, we provide flexible solutions for a wide range of industrial needs.

Not sure which product is right for you?

Try our configurator.