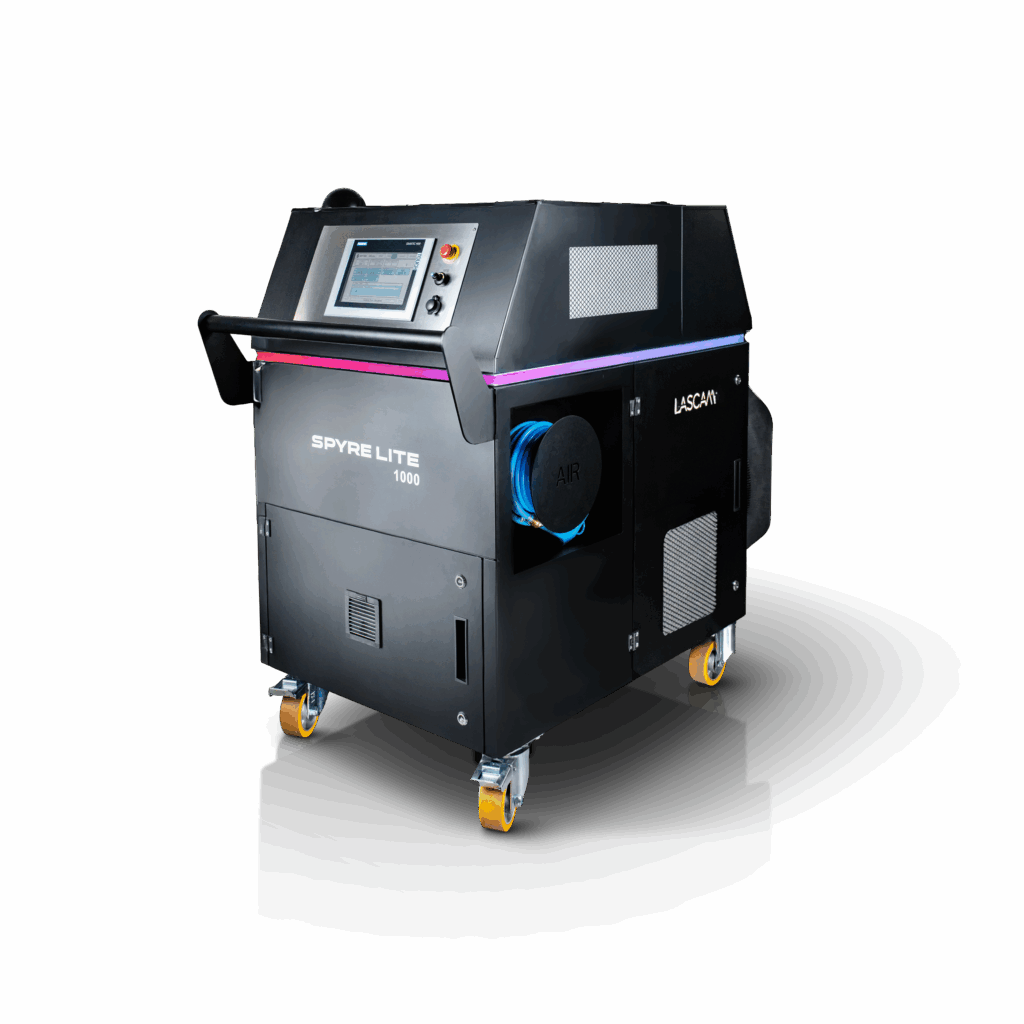

Our latest version of the laser cleaning system reflects customer demands for smaller and lighter chassis and laser processing heads with significantly decreased price due to the type of laser source. Light laser head with 3D printed parts made from titanium is newly designed with super ergonomics for user.

If you are looking to fully maximize your equipment’s potential, extend its service life, or to quickly and efficiently resolve all possible faults without unnecessary downtime, LASCAM systems is your reliable partner in providing comprehensive service. We will keep you moving forward.